Biodegradable Film

Description:

Characteristics

- Fully biodegradable into H₂O and CO₂ by burial or compost.

- High transparency and easy lamination without adhesive.

- Produced by cast extrusion for superior thickness uniformity.

- Suitable for printing, metalizing, and twisting.

- Laminated products maintain freshness for 5-7 days under refrigeration.

- 100% MIT (Made in Taiwan).

Applications

Molded fiber lamination, food-grade packaging films, envelope windows, paper bonding, plastic lamination, bread bags, bouquet sleeves, and more.

-

Come from Nature, Back to Nature

Extracted from plant-based sources, this film offers both durability and sustainability – making it easier to protect the planet.

Natural plants

Raw materials

Biodegradable films

Products

Compost and biodegradation

Photosynthesis

Environmental Advantages

Our biodegradable film is made from natural plant materials instead of petrochemical-based sources. Composed of 100% eco-friendly materials, it helps lower carbon emissions effectively. -

Products Thickness(µm) Max Width(mm) Max Length(M) Features PLF 25-100 1630 3000 Transparency PTL 25-100 1630 3000 Durability PLH 25-100 1630 3000 Heat Resistance For customized specifications or further inquiries, feel free to contact us via phone or email.

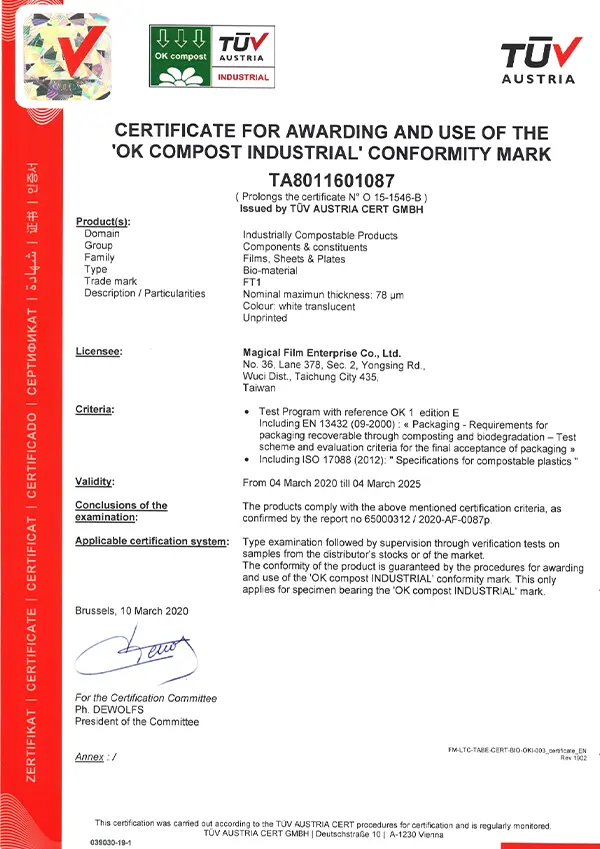

Strict Quality Control – Delivering Visible Excellence

Beyond third-party certifications, our in-house quality assurance team performs thorough inspections at every stage to guarantee that each batch meets the highest standards.

-

Molded fiber lamination

Food-grade packaging film

Envelope windows

-

Overview

Come from Nature, Back to Nature

Extracted from plant-based sources, this film offers both durability and sustainability – making it easier to protect the planet.

Natural plants

Raw materials

Biodegradable films

Products

Compost and biodegradation

Photosynthesis

Environmental Advantages

Our biodegradable film is made from natural plant materials instead of petrochemical-based sources. Composed of 100% eco-friendly materials, it helps lower carbon emissions effectively. -

Specifications

Products Thickness(µm) Max Width(mm) Max Length(M) Features PLF 25-100 1630 3000 Transparency PTL 25-100 1630 3000 Durability PLH 25-100 1630 3000 Heat Resistance For customized specifications or further inquiries, feel free to contact us via phone or email.

Strict Quality Control – Delivering Visible Excellence

Beyond third-party certifications, our in-house quality assurance team performs thorough inspections at every stage to guarantee that each batch meets the highest standards.

-

Applications

Molded fiber lamination

Food-grade packaging film

Envelope windows

Product Certifications

Plant Certifications