Film Production Technology

From material selection to final output, every step is meticulously controlled to ensure optimal quality.

Certified by ISO 22000:2018

Prodcuction Process

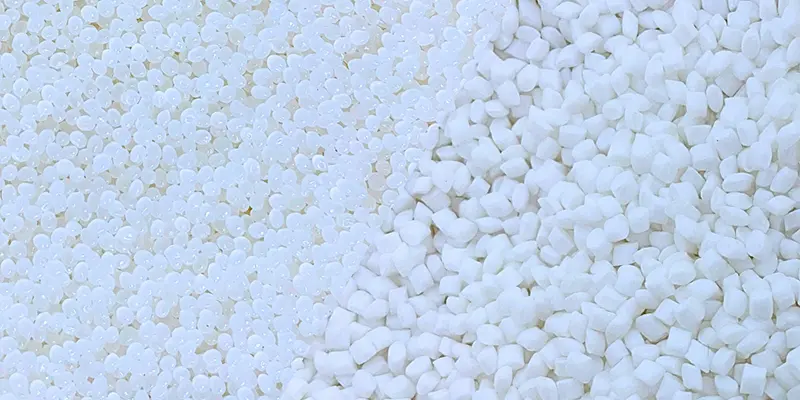

Raw Material

Plastic pallets are blended to prepare for the melting process.

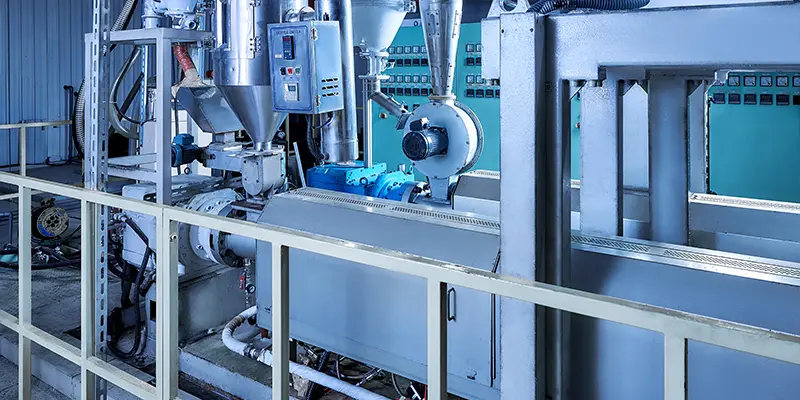

Hopper Dehumidification and Drying

Moisture is removed from the resin to stabilize the manufacturing conditions.

Heating and Melting

The material is heated to a molten state, allowing it to flow smoothly.

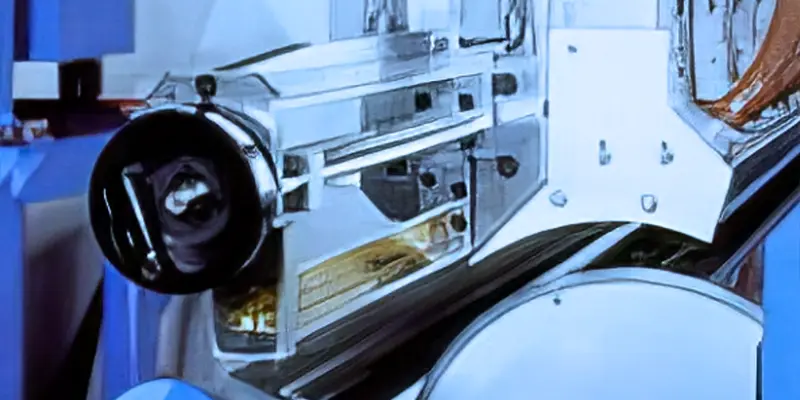

Die

Molten plastic is evenly extruded into a film form.

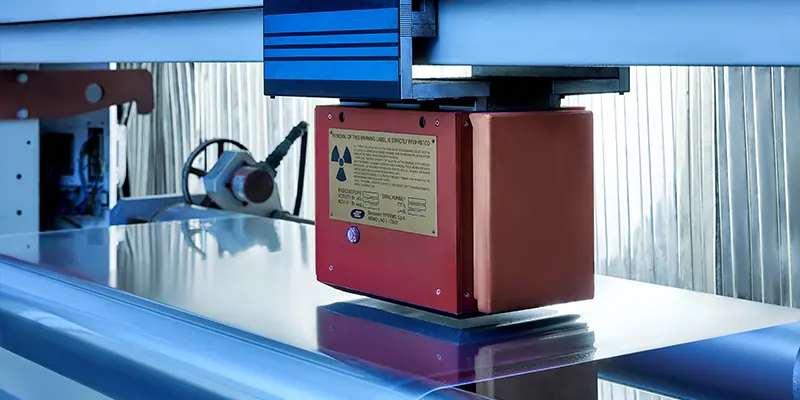

In-Line Inspection System

Film thickness is continuously monitored to maintain consistent quality.

Surface Treatment

Surface properties are enhanced to improve adhesion and versatility.

Edge Trimming

Excess edges are cut and recycled directly back into the production.

Winding

The finished film is uniformly wound into rolls for efficient storage and processing.

Rewinding and Slitting

Rewound and inspected for defects to ensure reliable performance.

Offline Quality Control

Manual inspection and sampling verification ensure product compliance.

Packaging

Rolls are securely packaged to safeguard them during transit and storage.

Shipping

Final inspection and boxed dispatch guarantee safe delivery to customers.