Mask Filtration Efficiency (FE) Testing Standards

| NIOSH 42CFR84 | ASTM F2299 | EN 149/13274 | EN 14683 | CWA 17553 | |

| Particles | MMAD 0.3 µm Polydisperse NaCI |

0.1 µm Monodisperse PSL |

0.06-0.1 µm Polydisperse NaCI |

3.0 µm S. Aureus Bacteria |

3.0 µm |

| Particle Charge | No Charge | No Charge | No Charge | No Charge | - |

| Item Tested | Entire FFR | Material Sample | Entire FFR | Material Sample | Material Sample |

| Flow Rate | 85 L/min | 28.3 L/min | 95 L/min | 28.3 L/min | - |

| Area Tested | 150 cm² | 100 cm² | 150 cm² | - | - |

| Velocity | 9.4 cm/s | 5 cm/s | 10.5 cm/s | - | 6 cm/s |

| Measurement | Mass, by Light Scatter | Count, by Light Scatter | Flame Photometry | - | - |

Filtration Efficiency (FE) Testing Methods for N95, FFP2, and KN95 Masks

| N95 (42CFR84) | FFP2 (EN 149) | KN95 (GB2626) | |

| Filtration Efficiency | ≥ 95% | ≥ 94% | ≥ 95% |

| Particles | Polydisperse NaCI | Polydisperse NaCI | Polydisperse NaCI |

| Flow Rate | 85 L/min | 95 L/min | 85 L/min |

| Tested by | NIOSH | Manufacturer | Manufacturer |

| No. FFRs Tested | 20 | 9 | 15 |

| Fit-Test: Total Inward Leakage | Not Required | ≤ 8% | ≤ 8% |

HEPA High-Efficiency Filters

High-Efficiency Particulate Air (HEPA) filters are air purification components widely used across medical equipment, automobiles, aircraft, and household systems. HEPA standards are set by the U.S. Department of Energy (DOE). Common HEPA filters can achieve up to 99.99% filtration efficiency, though variants with higher or slightly lower efficiency are available depending on national standards.

HEPA filter media are typically composed of randomly arranged synthetic or glass fibers. These fibers form a dense, fibrous matrix capable of capturing airborne particles through multiple mechanisms. According to filtration efficiency, filters are categorized as pre-filters, medium-efficiency filters, sub-HEPA filters, HEPA filters, and ultra-low penetration filtration air (ULPA) filters.

HEPA Grades

Following the U.S. DOE, a HEPA filter must remove at least 99.97% of airborne particles with a diameter of 0.3 microns (µm), which is also the standard adopted across most U.S. industrial sectors. In the European Union, HEPA classifications follow the EN 1822:2020 standard set by the European Committee for Standardization. This standard defines filter grades based on their performance against the Most Penetrating Particle Size (MPPS).

| HEPA Grades | Filtration Efficiency |

| H10 | > 90% |

| H11 | > 95% |

| H12 | > 99.5% |

| H13 | > 99.95% |

| H14 | > 99.995% |

| U15 | > 99.9995% |

| U16 | > 99.99995% |

| U17 | > 99.999995% |

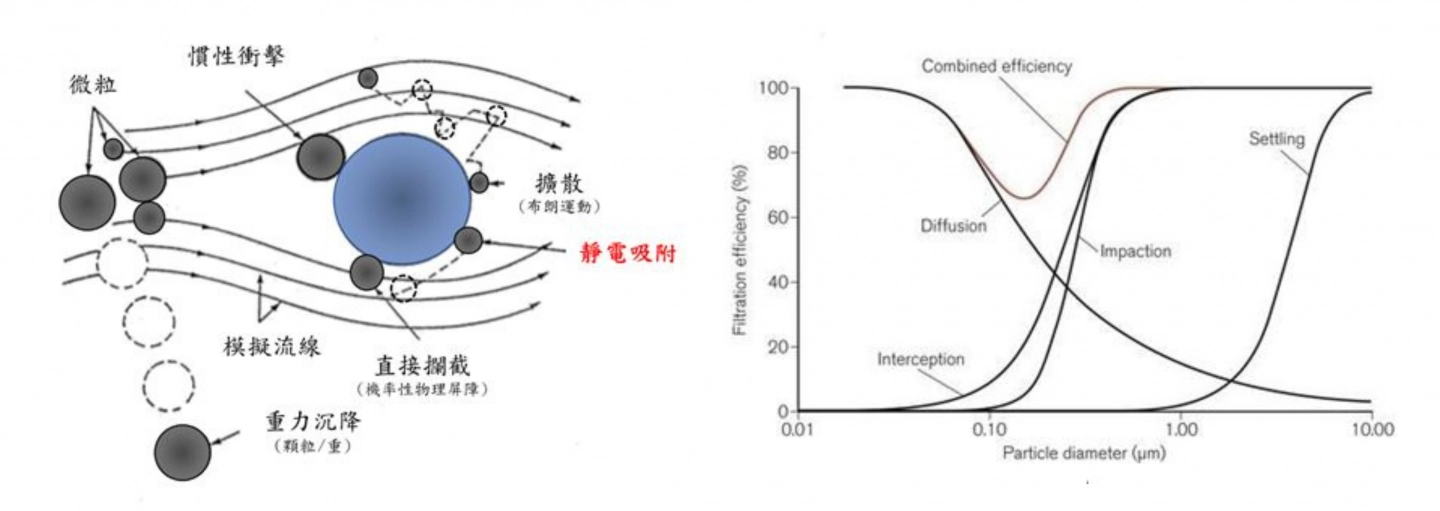

Why 0.3 Microns Matters

HEPA filters are specifically rated to capture particles sized 0.3 µm because they are the most difficult to filter. Smaller particles, such as those around 0.1 µm, are more easily captured due to Brownian motion, causing them to move erratically and collide with filter fibers. Moreover, larger particles (e.g., ≥ 0.4 µm) are more easily trapped via inertial impaction or direct interception. Particles around 0.3 µm, however, are in a range where none of these mechanisms are dominant, making them the hardest to capture—thus representing the critical benchmark for filter performance.

Diagram of filtration efficiency across particle sizes based on three mechanisms of inertial impaction, direct interception, and Brownian motion diffusion.

(From Anesthesia Key, Fig 11.2 accessed 8/6/20, Adapted from Hinds WC. Aerosol Technology. Properties, behaviour, and measurement of airborne particles. 2nd ed. New York: John Wiley and Sons; 1999.)