Photomicrograph resource: Taiwan Nonwoven Fabrics Industry Association

The Taiwan-born scientist, the hero behind the N95 respirator – Dr. Peter Tsai, has contributed to the research of electrostatic melt-blown nonwoven fabrics, increasing the bacterial and viral filtration efficiency 10 times more without decreasing the air permeability at Tennessee State University for 35 years. This technique has successfully become a milestone for N95 respirators and is also regarded as a crucial aegis for healthcare workers around the world.

The N95 respirator is a standard, not just a name.

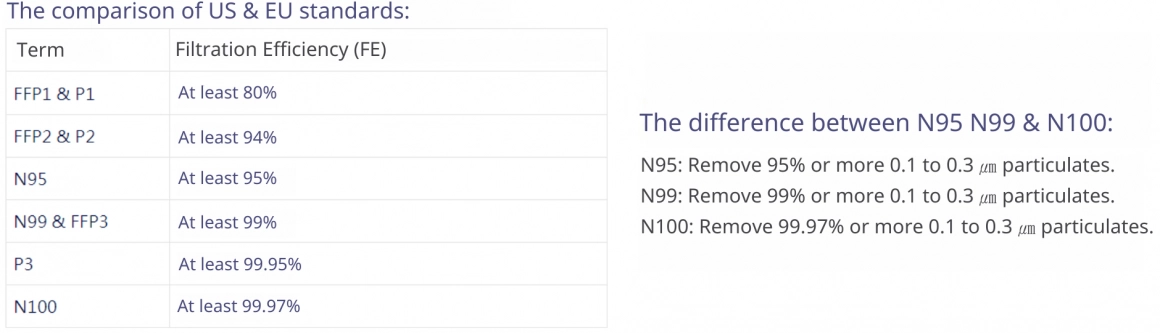

The N95 respirator is authenticated by the National Institute for Occupational Safety and Health (NIOSH) in America. N represents "not resistant to oil", and 95 means that the particle filtration efficiency (PFE) for non-oleaginous 0.3µm particulates reaches over 95% and the bacterial filtration efficiency (BFE) reaches over 99%.

Additionally, different countries have different terms for the N95 respirator. For example, FFP2 & FFP3 in the European Union, P2 in Australia, disposable DS2 and reusable RS2 in Japan, KN95 in China and KF94 in Korea.

Image resource: MEDTECS

Similar to the general medical masks, the main formation of N95 respirators is made of spun-bond nonwoven fabrics for the outer layer (moisture-proof), melt-blown nonwoven fabrics for the middle layer (filtration and adsorption) and spun-lace or hot-air nonwoven fabrics for the inner layer (skin-friendliness). However, there is only one filtration layer in medical masks; N95 respirators have double, and the filtration efficiency (FE) of each layer is higher than that in medical masks.

Compared with medical masks, N95 respirators not only possess the optimum seal of the edges but also are designed to perfectly fit the surface and contour of faces to prevent airborne particles from entering. Owing to the problems of gaps and air leaking on medical masks, the original filtration efficiency drops drastically from 78% to 40%.

Most significantly, the melt-blown nonwoven fabric plays a core role in filtration in N95 respirators. MAG-manufactured HEPA-grade melt-blown nonwoven fabric with PFE (99%+) and BFE (99%+) features lower air resistance and higher filtration efficiency. Furthermore, it is accredited by Nelson Labs, ROHS and FDA and has over 3.5 times the air permeability of others. The single layer of H12 and the double layers of H11 are the ideal formulas for N95 respirators.

The reusability of N95 respirators

To not damage or destroy the static charges on melt-blown nonwoven fabrics, the high-quality N95 respirator could be heated at 70°C for 30 minutes in the oven (do not place it on or close to the metals) and dry-streamed at 105°C to 117°C for 3 to 4 minutes in the rice cooker (do not place it directly at the bottom of rice cooker).

Please remember that disinfectants, suds, or any liquid containing bleach are not allowed to soak or sanitize N95 respirators because they will diminish the certain level of filtration efficiency and protection. After the heat treatment, please check if the shape of the N95 respirators affects the seal first; if not, the N95 respirators can be worn again.

For more information about MAG's MIT mask materials, contact us directly!

References:

MEDTECS- N95 Vs. KN95 Vs. FFP2 Vs. P2 Vs KF94-各國口罩防護分級全解析