What is nonwoven fabric?

The majority believes that nonwoven fabric is merely a kind of fabric, but it is more than this!

The nonwoven fabric includes the characteristics of the fabric and is bonded together through chemical, thermal, and mechanical approaches. It is neither processed via the traditional method nor knitted or woven. In addition, nonwoven fabric is commonly employed in filtration, medical gowns, wipes, hygiene products, diapers and other applications.

Different types of nonwoven fabrics?

The ingredients of nonwoven fabrics are divided into natural fiber and artificial fiber. Compared to the natural fiber, an artificial one is highlighted with lower cost, wider usage and contains the merits of natural fiber. The categories of nonwoven fabrics are hot-air, hot-roll, spun-lace, spun-bond, melt-blown and air-laid paper. In MAG, we produce both spun-bond and melt-blown nonwoven fabrics principally.

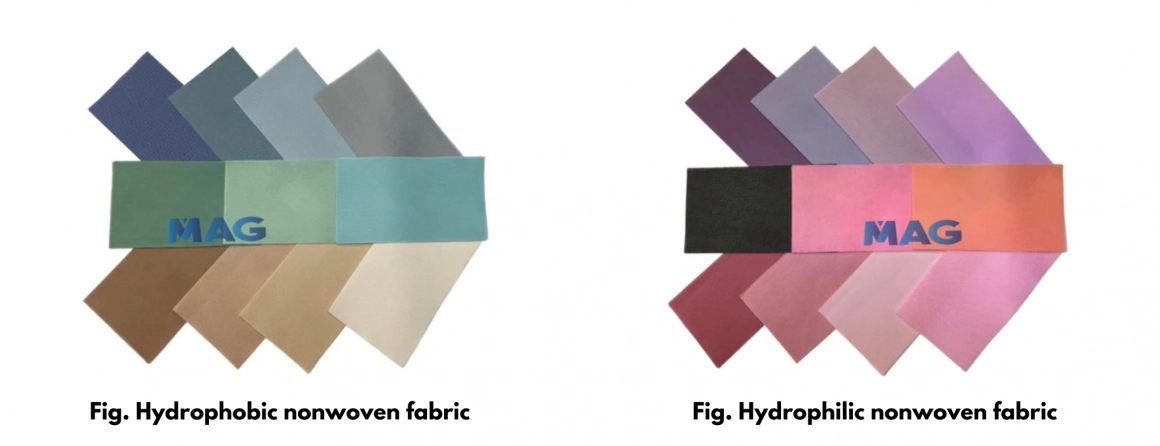

Spun-bond nonwoven fabric is composed of an integrated and bonded web formation, which is made of continuous filaments in a high-speed procedure. The excellent property of the fabrics facilitates the acceptability and feasibility in different areas of production. There are two kinds of spun-bond nonwoven fabrics, one is spun-bond hydrophobic nonwoven fabric and the one is spun-bond hydrophilic nonwoven fabric.

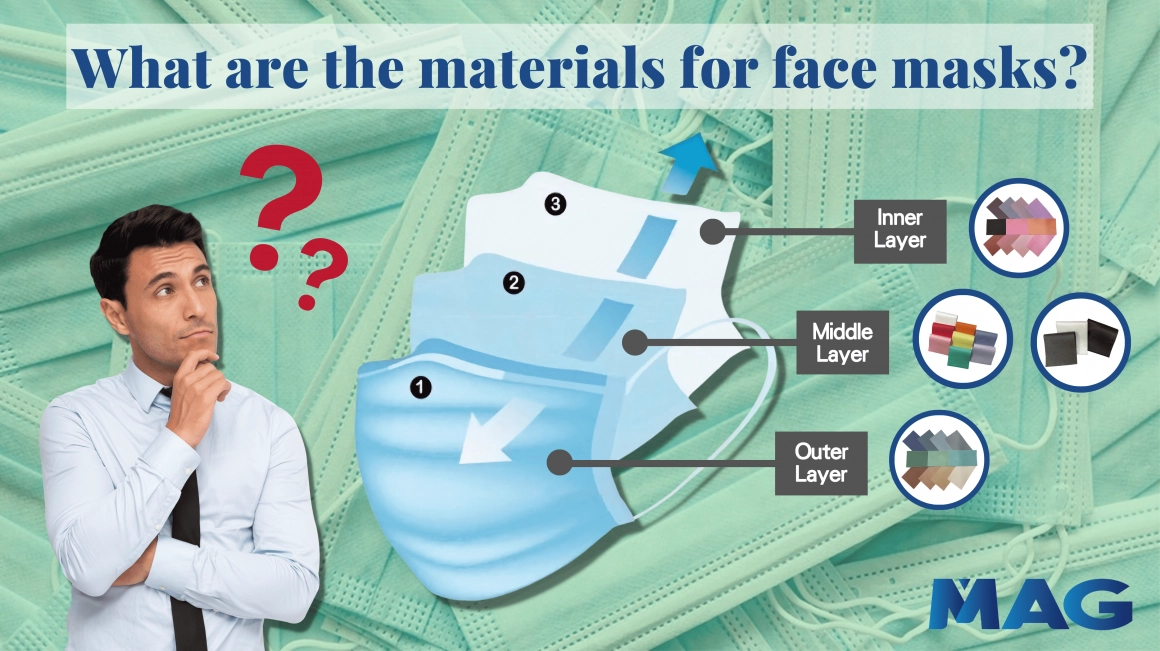

Spun-bond hydrophobic nonwoven fabric is used for the outer layer of face masks that possesses optimum support, waterproof, hydrophobicity, anti-blood penetration, etc.

Spun-bond hydrophilic nonwoven fabric is the material for the inner layer of face masks that acquires ideal hygroscopicity and absorbs droplets and steam to remain dry while breathing.

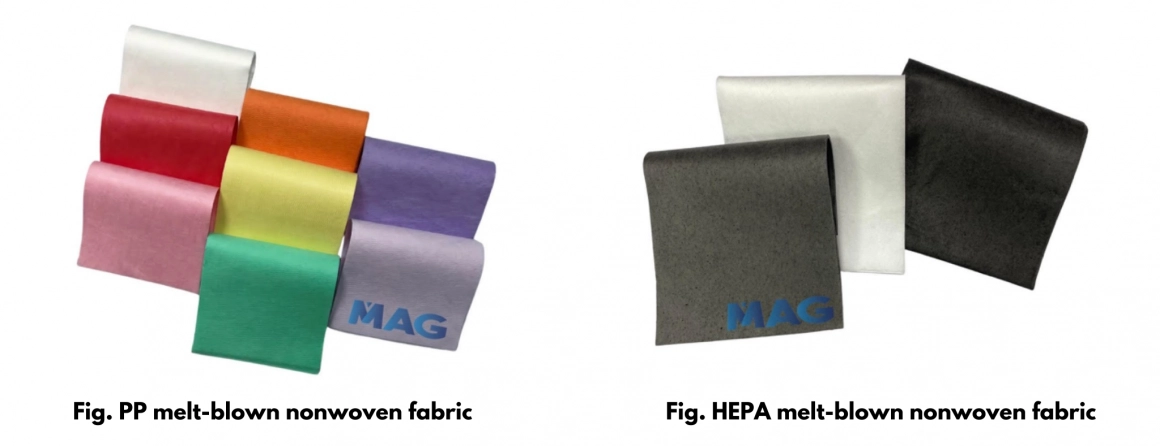

PP melt-blown nonwoven fabric is regarded as the heart of face masks and is known as the middle layer of face masks. It comes from the squeezed molten resin and implements the electrostatic technology to immerse each melt-blown nonwoven fiber with static. Besides, PP melt-blown nonwoven fabric features high density, low air permeability and is easy to absorb viruses and bacteria.

HEPA melt-blown nonwoven fabric is also another practice for the middle layer of face masks, providing lower air resistance and higher filtration efficiency with the water-electret technique. HEPA grade melt-blown nonwoven fabric can effectively remove at least 99% of 0.3μm up aerosols and prevent the spread of dust, pollen, PM 2.5, and dust mites.

Find MAG for MIT face mask materials!

Since MAG was established, we have constantly maintained the spirit of consumer safety and contributed to inventing colorful PP melt-blown nonwoven fabric with lower air resistance and higher filtration efficiency. MAG is the first and the sole company manufacturing the full ingredients of face masks. Furthermore, all products are certified and environment-friendly without any heavy metals, chemicals and other harmful substances.

Reference:

全球紡織資訊網- 防疫大作戰背後的熔噴不織布