Metal Nose Wire & Transformable Nose Wire

A Hidden Risk Behind the Mask?

While face masks are worn to protect us, incidents of injury caused by exposed or broken nose wires—especially in KF94 masks—have raised public concern. One such case involved a college student who was pierced by the metal wire of a face mask. These accidents highlight the importance of choosing the right nose wire material.

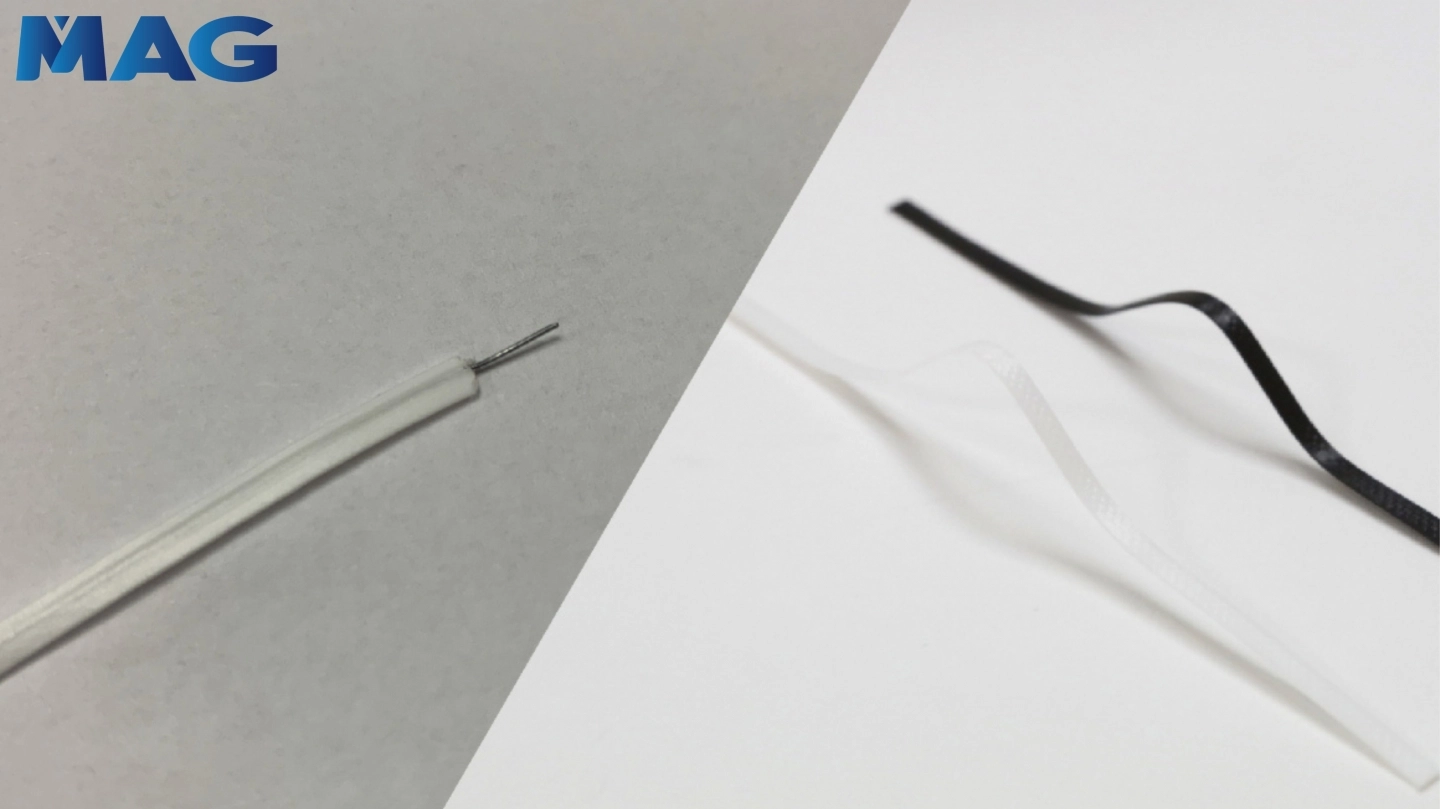

Metal Nose Wire vs. Plastic Nose Wire: A Comparison

The nose wire helps fit the mask closely to the face, enhancing protection against airborne particles. But not all nose wires are made the same. Here is a comparison of the two common materials:

| Feature | Metal Nose Wire | Transformable Nose Wire |

| Advantages | Strong shaping ability | Lightweight, flexible, and safe Comfortable to wear Environmentally friendly and recyclable |

| Disadvantages | Risk of injury from sharp or exposed ends May rust or break over time Heavier and harder to recycle |

Slightly lower shaping ability compared to metal |

KF94 masks often adopt double metal nose wires for a more secure fit, but this increases the risk of wire exposure. In contrast, transformable nose wires are safer, more comfortable, and increasingly favored by manufacturers due to their non-toxic, recyclable, and certified nature.

Certified Plastic Nose Wires from MAG

MAG offers high-quality, transformable nose wires that are non-toxic and certified to RoHS, SGS, and MSDS standards. Our nose wires are designed with user safety, comfort, and eco-friendliness in mind. In addition to nose wires, MAG also manufactures nonwoven fabrics, meltblown fabrics, and other anti-epidemic materials suitable for mask production.

Partner with MAG

Looking for reliable, certified materials for face masks or epidemic prevention products? Contact us for cooperation!

2024 Magical Film Enterprise Co., Ltd. All rights reserved.