Since the pandemic outbreak, MAG has dedicated itself to the comprehensive production of mask materials, including spunbond nonwovens, meltblown nonwovens, and nose wires to earloops to tackle the shortage of medical supplies. Notably, the meltblown nonwoven in the mask's middle layer, praised as the heart of the mask, plays a significant role in filtering viruses and bacteria. During this period, MAG produced 1920 tons of meltblown nonwovens, 2400 tons of spunbond nonwovens, and 1.9 billion masks for the Taiwan national anti-pandemic team. In 2021, the government honored MAG with the "Anti-pandemic Pioneer Award" for its high-quality products and services.

Following its outstanding performance in mask material production, MAG leveraged its extensive experience in Polypropylene (PP) nonwovens to launch two new PP products - oil-based absorbent pads and low-lint wipers, concentrating on addressing industrial oil pollution issues.

Oil-based Absorbent Pads

MAG's oil-based absorbent pad, particularly designed for industrial cleaning, is perfect for oil leaks or daily cleanup and features terrific corrosion, heat and abrasion resistance without fiber shedding. The heat resistance is examined and rated at the lowest fire hazard level to avert ignition.

The laminated surface holes treated with a heat-compressed point bonding process accelerate absorption efficiency and capacity. MAG's oil-based absorbent pad enables oil-based liquids to separate from water, absorbing more than 20 times its weight. The floating pads are easy to collect and recycle. After absorbing the oil-based liquids and squeezing them out, the absorption capacity of the pad may decrease by 10% to 15% but it remains reusable. The oil-based absorbent pad is available in three colors – white for oil-based absorption, yellow for non-oil-based absorption, and grey for both.

The excellent absorbency of oil-based absorbent pads are commonly used in maritime engineering, military, chemical or petrochemical plants, laboratories, pharmaceuticals, electronics technology, medical institutions, manufacturing industries, machinery factories, auto repair shops, dyeing, printing, food processing, kitchens, etc. Using MAG's oil-based absorbent pads helps protect the equipment and workplace while preventing any leaks and pollution.

The difference is after using MAG's oil-based absorbent pads.

The difference is after using MAG's oil-based absorbent pads.

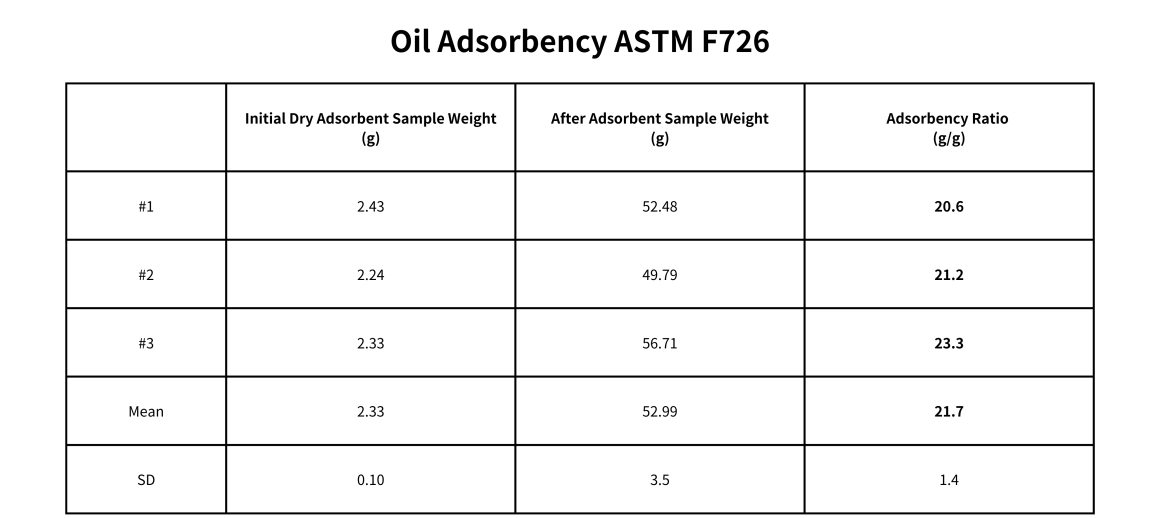

*The adsorbency ratio is over 20g/g.

*The adsorbency ratio is over 20g/g.

Low-lint Wipers

MAG's low-lint wiper with great oleophilic and hydrophilic properties is effective for high cleanliness requirements. The soft material of the wipers guarantees the integrity of surfaces and avoids scratches or damage to delicate parts. Due to its abrasion resistance, there is no fiber shedding or wiping marks. Whether used for dry or wet wiping, these wipes satisfy a wide range of applications. As the low-lint wipers are disposable, it is recommended to discard them after each use to ensure optimal cleanliness.

The low-lint wipers aim to remove dirt and dust from various surfaces. Therefore, they are suitable for the aviation industry, high-tech factories (electronics, semiconductor industries, etc.), GMP factories (medical biotechnology, cosmetics, food, etc.), machinery and mold manufacturing factories, chemical plants, automobile and motorcycle components, laboratories, printing, picture development, and other wiping purposes.

No fiber shedding or wiping marks after use.

Accumulating the technical expertise in mask material production, MAG successfully transitioned and applied the knowledge to new product areas, demonstrating its continuous innovation and keen understanding of market needs. Through oil-based absorbent pads and low-lint wipers, MAG will continue to drive further progress in industrial cleaning and workplace maintenance, thereby achieving mutual growth for the company and the customers.