Nonwoven Production Technology

From material selection to final output, every step is meticulously controlled to ensure optimal quality.

Certified by ISO 22000:2018

Production Process

STEP 01

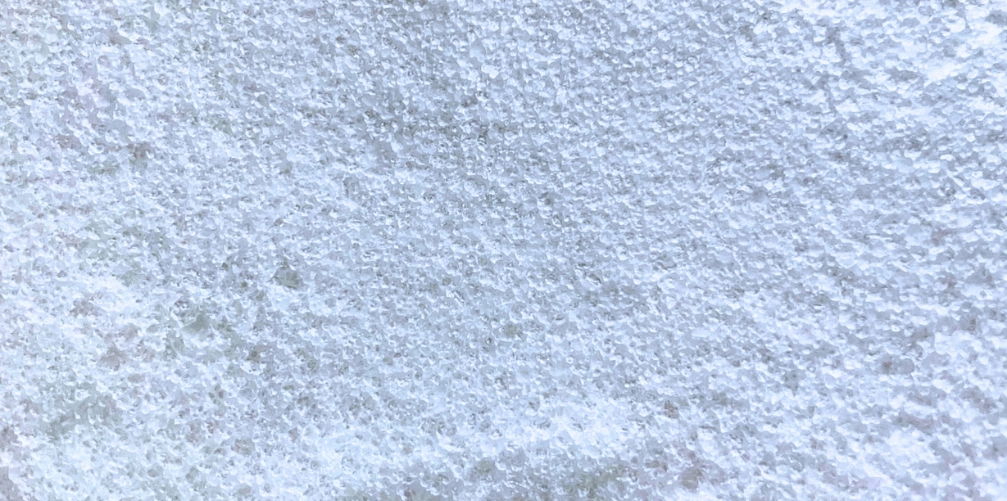

Raw Material

Plastic pallets are blended to prepare for the melting process.

STEP 02

Heating & Melting

Plastic pallets are heated and melted to prepare for filament extrusion.

STEP 03

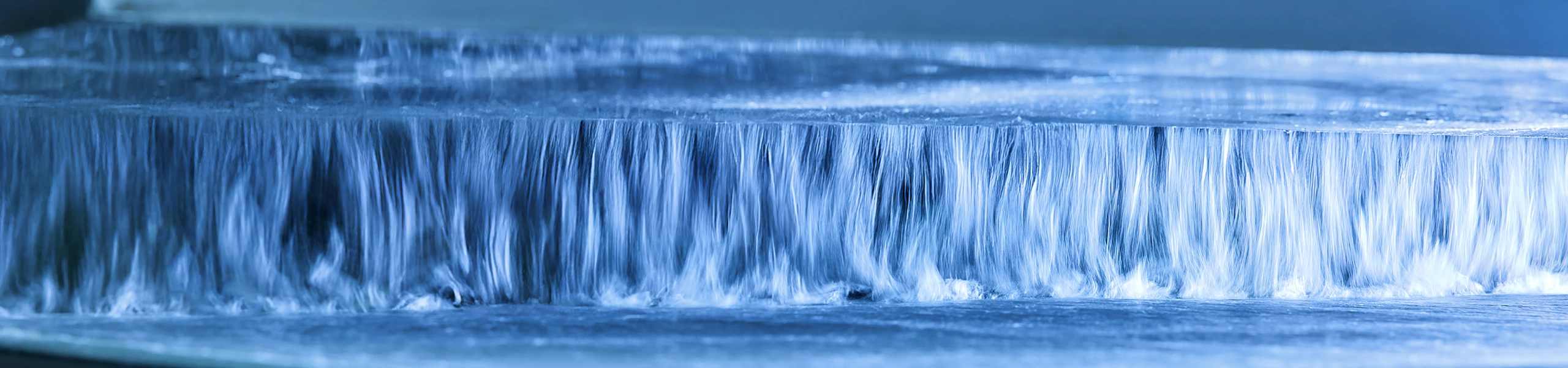

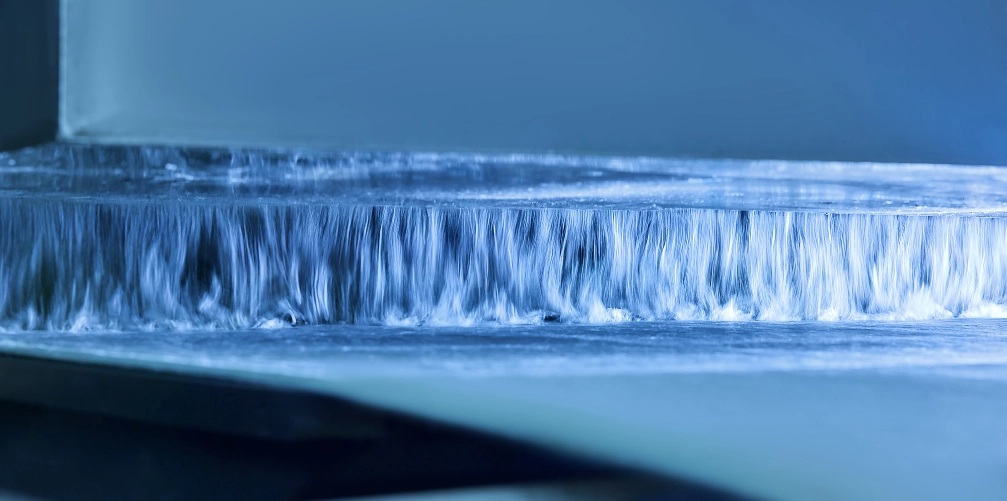

Fiber Attenuation

Molten polymers are stretched by high-velocity air to produce ultra-fine fibers.

STEP 04

Electrostatic Charging

An electrostatic field is applied to enhance filtration performance and adsorption capacity.

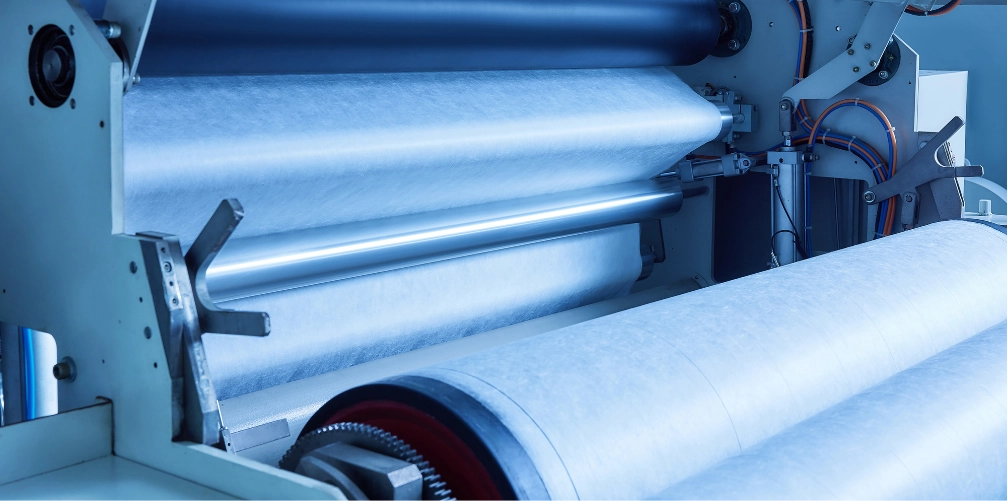

STEP 05

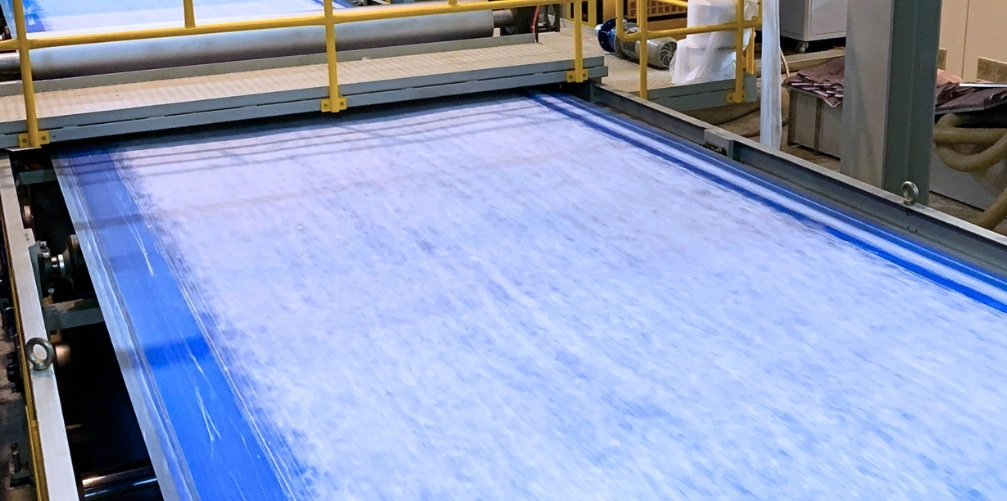

Web Formation

The attenuated fibers are uniformly laid to form a nonwoven fabric web.

STEP 06

Winding

The finished web is evenly wound into rolls for efficient storage and processing.

STEP 07

Packaging

Rolls are securely packaged to safeguard them during transit and storage.

STEP 08

Shipping

Final inspection and boxed dispatch guarantee safe delivery to customers.