Commercial Times and Economic Daily News have spotlighted MAG for its continued innovation and expansion into the high-efficiency filtration market.

With years of expertise in producing speciality films such as PET and PLA, MAG pivoted in 2020 to develop a complete line of anti-epidemic materials in response to the global shortage of medical supplies. This includes nonwoven fabrics, meltblown fabric, earloops, spunbond, and nose wires—all essential components in face masks and protective gear.

To meet growing demands for advanced filtration, MAG developed HEPA-grade meltblown materials suitable for use in face masks, air filters, protective coveralls, scrub suits, and other filtration and safety applications.

MAG currently maintains a stable monthly production capacity exceeding 100 tons, with a client base that spans across Europe, the Americas, Southeast Asia, and the broader Asia-Pacific region.

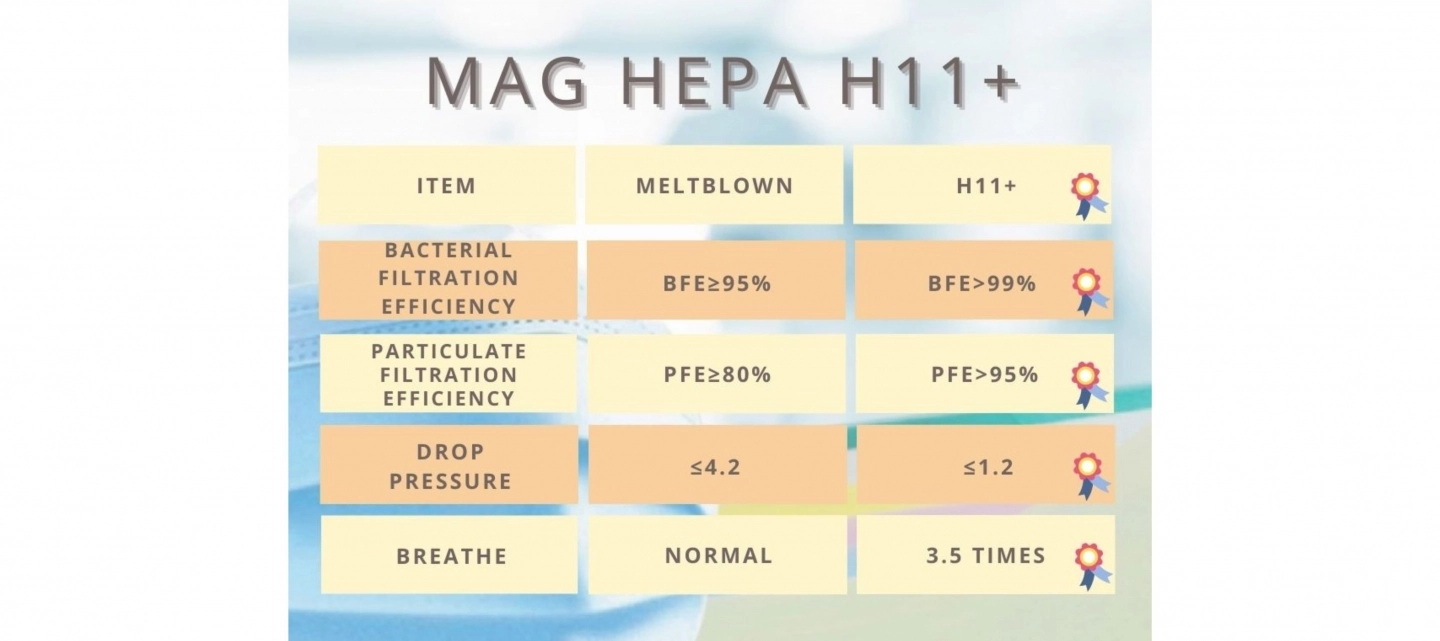

MAG H11+: High Efficiency, Low Pressure Drop

MAG's H11+ meltblown fabric stands out for its exceptional performance. Compared to standard meltblown materials, the pressure drop is under 1.5, and the breathability is improved by over 3.5 times.

This balance of high filtration efficiency and low airflow resistance makes it ideal for face masks that require both strong protection and long-wear comfort.